*This brand only supports repair, maintenance and other services

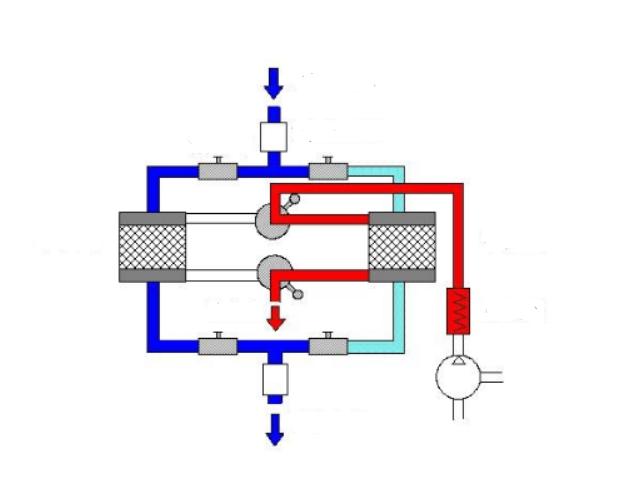

ThermalAir TA-5000A temperature forcing system is a quiet and eco-friendly heat flow hood system, which can conduct fast temperature test, fast cooling and heating cycle and temperature characteristics research and test on semiconductors (including printed circuit boards and other components). Compared with competitors, TA-5000A adopts DC variable control compressor, which improves the temperature control stability in the range of - 80 ℃ to+225 ℃. Provide air flow for continuous operation at a flow rate of up to 24 SCFM.

Our professional team has decades of industry experience, and has been working closely with well-known domestic enterprises for a long time. We provide nationwide rapid support for equipment failure of MPI ThermalAir rapid cycle temperature shock system, and can provide high standard repair, maintenance and reconstruction (reconstruction) services in our factory.

Our services

ThermalAir repair and maintenance, sales of raw materials

Renovation of ThermalAir equipment

Thermal Air equipment transformation

Transformation and maintenance of ThermalAir air circuit system

Sales and maintenance service of ThermalAir compressor

ThermalAir temperature calibration

ThermalAir system maintenance

Temperature Forcing System heat shield leasing

Support the heat flow instrument Temperature Cycling System exchangeable return to the factory for maintenance

Service standards

Speed: respond within 1 hour and provide implementation plan within 24 hours.

Profession: many engineers have been with the Temperature Cycling System for more than 10 years.

Maintenance: standard service of the original factory.

Material: original brand material.

Support: provide exchange maintenance.

Information: update and backup equipment files, and be the housekeeper of customer equipment.

Model of service

|

Brand |

Type |

||

|

ThermalAir |

TA-5000A/B |

TA-3000A |

TA-1000 |

Our professional knowledge and experience means that we can provide comprehensive advice and support for the application and maintenance of most heat flow instrument Temperature Cycling System. Through the design and transformation of the system (customized or configured according to the site environment), we can provide a complete system solution.