Power Management Integrated Circuits (PMIC) is a chip responsible for Power conversion, distribution, detection and other Power Management responsibilities in electronic equipment systems. In the design of power supply, it is necessary to use various forms of management chips. Under the electrical test, with the change of power supply temperature, it is necessary to ensure the normal operation of the chip. Generally, the higher the temperature of the chip, the lower the reliability, and the higher the failure rate will be. Therefore, temperature should be considered at the beginning of chip design.

PMIC power management chip because many are working in narrow space, the conditions of the heat dissipation is not good, work long hours are mostly in high temperature environment, frequent experience rapid heating up, a power supply chip even experienced rapid warming in voltage instability, so the power chip in the factory need to pass the test chip in the process of rapid temperature stability, Chinacryo ThermoTest provides a fast impact temperature range of -100°C to +350°C, suitable for all types of PMIC power management chip high and low impact testing.

In terms of reliability test of power management chip, Chengdu ChinaCryo Technologies CO.,LTD ThermoTST TS series Temperature Forcing Systems has unique advantages compared with traditional high and low temperature box: Fast temperature change rate, rapid temperature rise/drop of 15°C per second, real-time monitoring of the real temperature of the components under test, can adjust the impact air temperature at any time; For a single IC(module) of many components on the PCB, the impact of high and low temperature is carried out independently without affecting other peripheral devices; It can be used with advantest, Teradyne, Keysight, Verigy and other engineering machines.

| type |

TS-760 |

TS-780 |

TS-790 |

| Temperature Range °C |

-65 ºC to + 225 ºC | -80 ºC to + 225 ºC | -90 ºC to + 225 ºC |

| Typical Temperature Transition Rate |

-55 ºC to + 125 ºC ; about 10 seconds | -55 ºC to + 125 ºC ; about 10 seconds | -55 ºC to + 125 ºC ; about 10 seconds |

| Air drying system |

built-in |

built-in |

built-in |

| Operation Interface |

Color touch screen |

Color touch screen |

Color touch screen |

| System Airflow Output scfm |

4 ~ 18 SCFM(1.9L/s ~ 8.5L/s) | 4 ~ 18 SCFM(1.9L/s ~ 8.5L/s) | 4 ~ 18 SCFM(1.9L/s ~ 8.5L/s) |

| Temperature Set, Display and Resolution |

+/- 0.1°C |

||

| Temperature Accuracy |

1.0°C(Calibration according to CANS certification unit) |

||

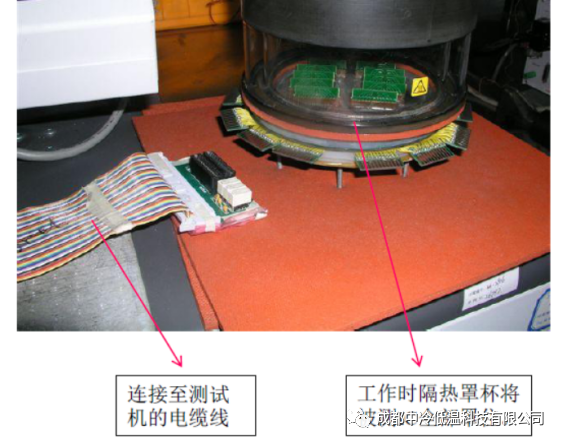

Ts-780 is used for PMIC power management chip high and low temperature impact test case: a customer produces a power supply chip company. The following figure shows the actual tested power supply chip, welded to a PCB board. Temperature test is required with electricity on. The test temperature range is -60℃ ~ 150℃, and 12 groups of different forms of cycle temperature setting are carried out.

Ts-760 is used for PMIC power management chip high and low temperature impact test case: a customer developed a power management chip company, the chip test temperature range requirements -40 to 80 degrees, in the electrical test, at the same time with a tester, set different temperature values, check whether the power chip functions under different temperatures. By using this equipment, work efficiency is greatly improved and potential problems in the development process can be assessed in a timely manner.

Ts-345 in PMIC power management chip high and low temperature impact test case: a customer company, due to the use of closed laboratory, and the chip -40 to +80 degrees online test, the conventional model customer felt too loud, finally choose TS-345 low noise portable high and low temperature impact machine test.